3M – EXL UW 3X1/4X1/4 (75X6X6) – 2A MED

₹10,480.00₹12,052.00 (-13%)

Typical properties

Details

|

Abrasive Material |

Aluminum Oxide |

|

Application |

Deburring, Finishing, Blending, Refining |

|

Attachment Type |

Center Hole |

|

Brands |

Scotch-Brite™ |

|

Center Hole Diameter (Imperial) |

0.25 in |

|

Center Hole Diameter (Metric) |

6.35 mm |

|

Density |

2 |

|

Equipment – Machines |

Bench Top Motors, Die Grinders |

|

Face Width (Imperial) |

0.25 in |

|

Face Width (Metric) |

6.35 mm |

|

Grade |

Medium |

|

Industries |

Food & Beverage, Metal Fabrication, Metalworking, Aerospace |

|

Maximum Speed |

12100 rpm |

|

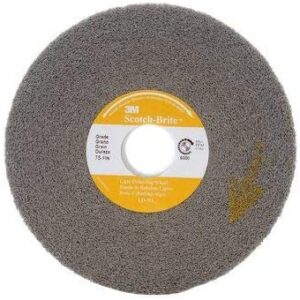

Product Color |

Gray |

|

Product Form |

Unitized Wheel |

|

Sub Applications |

Blending, Contour Finishing, Deburring Edges, Refining, Edge Radius, Edge Break, Aesthetic Finishing, Weld Removal & Finishing |

|

Sub Industries |

Metal Fabrication, Metal Implants, Medical Instruments, Plumbing Fixtures, Turbine Engines, Builders Hardware |

Dimensions and Classifications

|

Overall Diameter (Imperial) |

3 in |

|

Overall Diameter (Metric) |

76.2 mm |

Minimum Order Quantity 40

Scotch-Brite™ EXL Unitized Wheel, XL-UW, 2A Medium, 3 in x 1/4 in x 1/4 in

Effective Smoothing, Deburring, and Finishing

Scotch-Brite™ EXL Unitized Wheels feature a soft, conformable consistency that effectively smooths, deburrs and finishes the edges of metal alloys, as well as many plastics and composites. There are a variety of densities and grades starting from a very soft 2 density for applications requiring conformability to a hard, aggressive 8 density for maximum cut and durability.

Key Features

-

Soft yet durable unitized construction for long-lasting use

-

Conformable design reaches complex shapes and contours

-

Resists smearing for a cleaner finish and reduced prep time

-

Operates in both clockwise and counterclockwise directions

-

Minimizes heat build-up, ideal for heat-sensitive materials

-

Available in multiple densities and grits (from very soft to aggressive)

-

Compatible with die grinders and robotic deburring tools

Best For

-

Deburring metal alloys, plastics, and composites

-

Edge smoothing and fine finishing applications

-

Robotic finishing and end-of-arm tooling operations

-

Applications requiring consistent surface conditioning

-

Projects where low heat generation is critical

Reviews

There are no reviews yet.