3M Scotch-Brite™ EX3 Deburring Wheel, X3-WL, 9S Fine, 6 in x 1 in x 1 in

₹10,275.00₹21,311.00 (-52%)

|

Abrasive Material |

Silicon Carbide, Aluminum Oxide |

|

Application |

Polishing, Finishing, Deburring |

|

Attachment Type |

Center Hole |

|

Brands |

Scotch-Brite™ |

|

Center Hole Diameter (Imperial) |

1 in, 1.25 in, 3 in, 5 in, 8 in, 10 in |

|

Center Hole Diameter (Metric) |

25.4 mm, 31.75 mm, 76.2 mm, 127 mm, 203.2 mm, 254 mm |

|

Density |

8 , 9 |

|

Equipment – Machines |

Manual Backstand, Inline Sanders |

|

Face Width (Imperial) |

0.25 in, 0.5 in, 1 in, 2 in |

|

Face Width (Metric) |

6.35 mm, 12.7 mm, 25.4 mm, 50.8 mm |

|

For Use On |

Composites, Soft Composite, Glass, Hard Composite, All Metals |

|

Grade |

Fine, Medium |

|

Industries |

Metalworking |

|

Maximum Speed |

2550 rpm, 3000 rpm, 3600 rpm, 4500 rpm, 6000 rpm |

|

Product Color |

Gray |

|

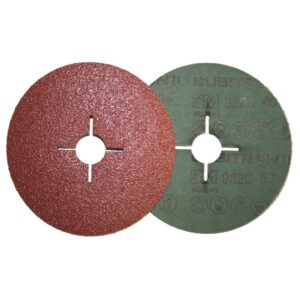

Product Form |

Wheel |

|

Sub Applications |

Blending, Flat Finishing |

|

Sub Industries |

Turbine Engines, Plumbing Fixtures, Medical Instruments, Builders Hardware, Metal Fabrication, Metal Implants |

|

Price Per Unit |

₹5825 |

|

Overall Diameter (Imperial) |

4 in, 6 in, 8 in, 10 in, 12 in, 14 in, 16 in, 18 in |

|

Overall Diameter (Metric) |

101.6 mm, 152.4 mm, 203.2 mm, 254 mm, 304.8 mm, 355.6 mm, 406.4 mm, 457.2 mm |

Each Box Contains 3 Pieces

Scotch-Brite™ EX3 Deburring Wheel – Hard-Density, High-Precision Edge Deburring

The Scotch-Brite™ EX3 Deburring Wheel is a convolute-constructed, high-density deburring wheel engineered for demanding applications where edge retention, durability, and minimal smearing are essential. Ideal for sharp metal burrs and edges, this industrial-grade wheel provides consistent performance with minimal heat build-up—making it a reliable solution for metals, composites, and glass.

Key Features :

-

Superior Edge Retention

Best suited for parts requiring precision edge definition, not recommended for conformable or flat surface finishing. -

Heat & Smear-Resistant Resin System

Ensures cool running and reduces discoloration, improving part quality and reducing rework. -

Versatile Mineral Options

-

Silicon Carbide: Sharp, fine finish, ideal for low-pressure polishing or prep work.

-

Aluminum Oxide: Tough, long-lasting, and perfect for aggressive material removal.

-

-

Wide Range of Material Compatibility

Works on glass, hard and soft composites, and metals—including:-

Builder’s hardware

-

Medical instruments

-

Metal fabrication parts

-

Implants and turbine components

-

Plumbing fixtures

-

-

Consistent Performance Throughout Product Life

Open-web construction resists loading and exposes fresh abrasives, maintaining high cut rate over time.

Best For :

-

Edge deburring of precision metal parts

-

Finishing of composite and glass edges

-

Polishing metal components in aerospace, medical, or plumbing industries

-

Blending and cleaning hard-to-reach burrs on sharp profiles

Reviews

There are no reviews yet.