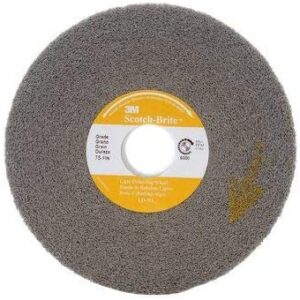

3M Scotch-Brite™ EXL Unitized Deburring Wheel 3″ x 1/4″ x 1/4″ – 3S FIN

₹24,920.00₹25,244.00 (-1%)

| Features | Details |

|---|---|

| Brand | 3M |

| Sub-Brand | Scotch-Brite™ |

| Product Type | EXL Unitized Deburring Wheel |

| Part Number | 002327 (approximate) |

| Grade | 3S FIN (Fine) |

| Abrasive Material | Aluminum Oxide |

| Diameter | 3 inches (76.2 mm) |

| Thickness | 1/4 inch (6.35 mm) |

| Arbor Hole Size | 1/4 inch (6.35 mm) |

| Construction | Unitized, non-woven abrasive |

| Density | Medium (for controlled deburring) |

| Operating Direction | Bi-directional |

| Applications | Deburring, Edge Finishing, Surface Preparation |

| Tool Compatibility | Die Grinders, Rotary Tools, Robotic Systems |

| Cutting Action | Cool, consistent cut with minimal smearing |

| Finish Quality | Smooth, burr-free edges |

| Price per Unit | ₹623 |

Each Box Contains 40 pieces

3M Scotch-Brite™ EXL Unitized Deburring Wheel 3″ x 1/4″ x 1/4″ – 3S FIN

The 3M EXL Unitized Deburring Wheel is a high-performance finishing tool designed for precision edge conditioning on a variety of materials. Its 3-inch diameter and ¼-inch thickness make it ideal for use with standard die grinders and robotic end‑effector tooling.

Key Features :

-

Conformable, Layered Construction — Built with unitized layers of non-woven nylon infused with abrasive minerals (aluminum oxide or silicon carbide), this wheel stays in consistent contact with contoured surfaces and complex shapes .

-

Dual-Direction Capability — Safe to run clockwise or counterclockwise, offering flexibility in deburring operations .

-

Low Heat & Smearing — Engineered to resist heat buildup and smearing during use, making it suitable for heat-sensitive substrates .

-

Variety of Densities/Grades — Available in soft to aggressive densities and in fine (FIN) grade—perfect for delicate, controlled edge finishing .

-

Robotic Deburring Ready — Offers consistent performance over its lifespan, making it ideal for automated deburring in industrial environments .

Best For :

-

Deburring, Finishing & Polishing of edges on metal alloys, plastics, and composite materials.

-

Surface Preparation—Refines edges for weld prep or coating adhesion.

-

Edge Conditioning—Delivers smooth, burr-free edges without altering part geometry.

Reviews

There are no reviews yet.